On November 1~4, the Asia Pacific region the most watched annual event - the 2016 Asia international logistics logistics technology and transportation system Exhibition (referred to as the "Asian logistics exhibition", CeMAT Asia 2016) was held at the Shanghai New International Expo center. This exhibition focus on intelligent logistics, fine division of the system integration and solutions, transportation equipment, automatic guided vehicle (AGV), forklift and accessories, lifting equipment and accessories, pallets and shelves, automatic recognition and machine vision, logistics robot eight theme exhibition, attracted more than 500 well-known global enterprises participating in 52000 square meters of exhibition area, the internationalization of logistics feast in four days for the audience presented a seat, include material handling, automation technology, transportation system and many other content.

As the authority of the media of the logistics industry, "Journal of logistics technology and application" grand attended the event, the reporter sent over the on-site interview, also held a magazine promotion, readers draw, customer communication and other activities, and through the official WeChat magazine platform (LMH_56) for real-time video and text coverage of the exhibition, covering exhibitors showcase innovative products and solutions, market application, enterprise development target, industry trend analysis, full of dry cargo. It is worth mentioning that, as the "technology and application" logistics magazine one of a series of activities during the exhibition, Chinese apparel logistics innovation development alliance by my agency initiated the establishment of the opening of the exhibition held on the day before the "China apparel Logistics Innovation Development Alliance Salon (ShangHai Railway Station)" activities successfully.

In recent years, the "4 industry" and "intelligent manufacturing" concept of communication and electronic commerce has greatly promoted the development of A new force suddenly rises., and the application of intelligent logistics, China logistics equipment market for intelligent logistics automation equipment, increasing demand, logistics has become a hot field of Intelligent City, and gradually evolved into the core competitiveness of enterprises. The logistics system integrators clearly see this point, will have their own focus on intelligent logistics; the rapid development of electronic commerce, changing consumer shopping habits and the operation pattern of enterprises, enterprises urgently need to speed up the processing speed of the order to deal with the multi varieties, small batch, multi batch orders and fragmentation rising labor costs brought enormous pressure, "goods to people" system to store the density to highlight, high sorting efficiency, reduce labor intensity, saving the amount of labor and other advantages become the key direction for the development of the industry; as a logistics system integrator, is able to provide integrated supply chain solutions, has become an important factor to test the strength of enterprises in addition, with the China; logistics equipment market matures, the market competition is increasingly fierce integrators, in addition to the products and solutions of innovation, also put more focus on the stability of equipment, adaptability and flexibility. In this year's CeMAT Asia exhibition, the industry characteristics and trends have been fully displayed.

Fu, Tektronix, SSI Schaefer, Swisslog de TGW, and Murata, Kunchuan, Vanderlande industries North giant integrated industry institute, from the north, SIASUN, today international, Wu Qiang, hi tech, corundum, Shen Fei, Ding Tianda, well integrated, in pine and other domestic and international logistics system brings together, showing the logistics the latest equipment and solutions, technology competition staged a big coffee show.

With this year CeMAT Asia theme "focus on intelligent logistics", Dema Taco International Trading (Shanghai) Co., Ltd. (hereinafter referred to as "Dema Taco") in the exhibition for the first time to the users in Asia show "goods to robot" solutions, advanced concepts, product innovation, has attracted countless viewers to stop. It is understood that the solution is mainly composed of automatic mixed boxes palletizing system, multi shuttle system, RapidPick XT robot picking workstation etc.. Damon Tektronix solutions department director Deng Jianyi said, from the "goods to people" to "delivery robot", which is the inevitable trend of the development of the industry.Compared with the "goods to solve the" plan "goods to the robot" competitive advantage. He told reporters introduce RapidPick XT picking robot workstation.

The robot has multi load processing capability, and multi shuttle, can realize the efficient zero selection can also be used in automatic palletizing, automatic sorting and automatic packing material box orders and other sectors, can help even replace the manual to execute the order to fulfill future. The main features include: 365 days and nights, 7x24 hours of continuous work; in 1200 / hour high picking efficiency to maintain 100% accurate; in accordance with the order specified in a work space flexible chose different properties and packaging of goods; the error rate can reduce manual operation, improve the order fulfillment time that is especially beneficial for the development of the electricity industry.

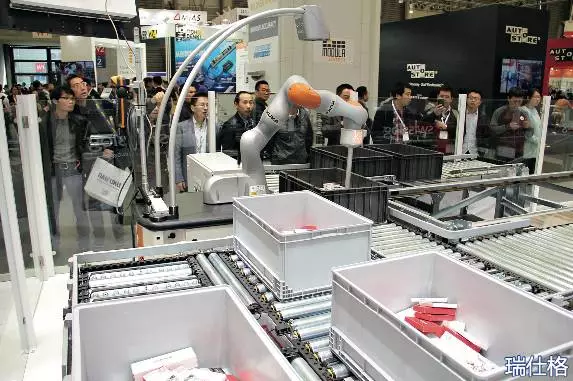

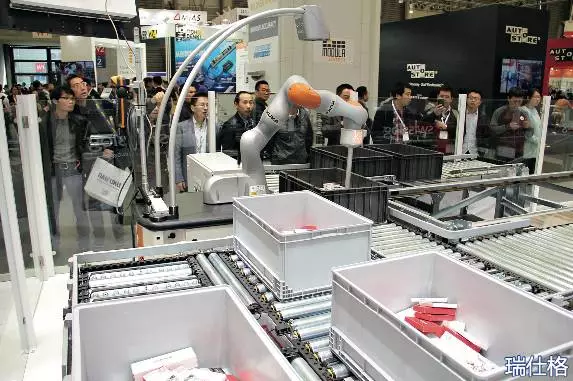

Rui Shige (Shanghai) Trading Co., Ltd. (hereinafter referred to as "Rui Shige") with "intelligent logistics to assist your business growth" as the theme, through the display of the robot selection scheme of dynamic light load cargo storage system of the new generation of high efficiency and intelligent combination, high efficiency, flexibility and reliability of the have a future warehouse. Rui Shige East Asia managing director Huang Junfeng told reporters, in order to meet the retail, electricity providers, pharmaceutical and food and beverage industry the demand of high throughput, Rui Shige developed a new type of shuttle vehicle technology -- Cyclone Carrier, for storing and conveying carton, tray and box, with a high degree of flexibility and availability; award-winning advanced light technology -- robot picking system (AIP) by using the KUKA high sensitivity light touch robot LBR iiwa, you can choose the fast mode, can realize man-machine collaboration, significantly improve the performance of chosen; Rui Shige is the pursuit of high efficiency, high storage density and provide customers with PowerStore tray shuttle system. This is a deep automatic tray type dense storage scheme, pallet can handle up to 1.5 tons of weight, in the room (or the minimum to -30 DEG C) using cryogenic refrigerator. Huang Junfeng said that the traditional logistics has become the past, Rui Shige will deeply understand the "4 industry" concept, to be modified as the center, to the individual needs as the basis, to provide internal logistics more efficient solutions for customers.

As the world's leading logistics system integrators, the blessing of the exhibition showcased its exclusive box (box) ultra high speed automatic warehouse system -- Seth Dole (DUOSYS), a live demonstration attracted many visitors stop. According to Fu (China) director / logistics equipment limited company sales director Zhu Li introduced, the unique feature of the system is designed with two layers structure, using 4 stacker running simultaneously in an automated warehouse, due to the use of synchronous control technology, stacker can independently work, do not interfere with each other the system of storage, processing capacity of up to 2200 boxes (boxes) per hour, reached the world top level storage capacity, especially suitable for many varieties, small batch, multi batch fast storage applications.

As a provider of intelligent manufacturing and intelligent logistics system of a professional, today international logistics technology Limited by Share Ltd (hereinafter referred to as "international today") in the display box describes in detail the independent research and development of WMS WCS and other core software and tunnel type stacking machine, automatic guided vehicle, shuttle car core equipment; and brought a classic case of the rich diversity, explore the different characteristics of the industry and the demand of logistics automation and intelligent, starting from the actual production logistics, warehousing and distribution as well as the networking problems. It is worth mentioning that, in August 18, 2016, today the international success of landing the Shenzhen Stock Exchange gem, which will undoubtedly bring a strong financial support for their further development. Today said the general manager of the international Third Division Chen Dongwei told reporters, today the international IPO will raise funds for research and development and product logistics automation system of industrial projects, construction projects, technology experience center automation equipment assembly logistics base construction project and other aspects.

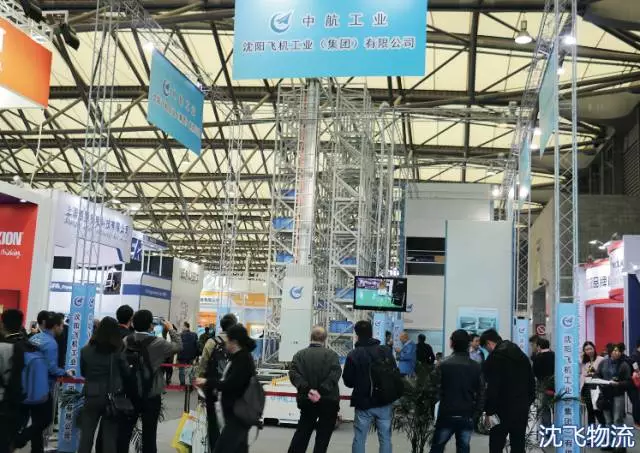

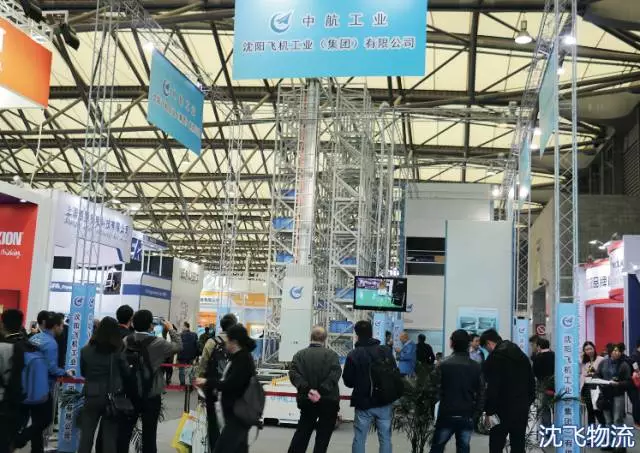

Shenyang Aircraft Industry Group Logistics Equipment Co. Ltd. (hereinafter referred to as "Shen Fei Logistics") as a well-known domestic logistics system integrators and logistics equipment manufacturer, display light high speed stacker (MiniLoad), AGV, vertical carousel, vertical lifting base four intelligent logistics system and equipment. Among them, the good performance of MiniLoad, speed up to 360 m / min; compared to the vertical carousel and before the show, the appearance of innovation, more beautiful and easy to operate; the vertical lifting base adopts gear rack transmission technology, bearing reached more than 500kg, and has long service life, maintenance free advantages; independent research and development of AGV mature and stable product. Shenfei logistics general manager Tan Yanbin told reporters that at present these systems and equipment has been widely used in many industries.

Jiangsu hi tech logistics Polytron Technologies Inc (hereinafter referred to as "hi tech logistics") rapid development in 2016, has made two major breakthroughs: one is to create a number of intelligent solutions in the industry; two is the product in intelligence by extension. Hi Tech logistics show Beijing Tongrentang, Huishan, Shenyang non-staple food, beauty appliances, medicine, food, Suzhou Cody, Hangzhou metro, Mengniu Dairy and many classic cases in the exhibition. Hi Tech Logistics Manager Yu Naiyi said, the current logistics equipment market demand is very strong, but at the same time, competition is more intense, hi tech logistics will seize market opportunities, through innovative products and solutions for customers to create excellent project plan.

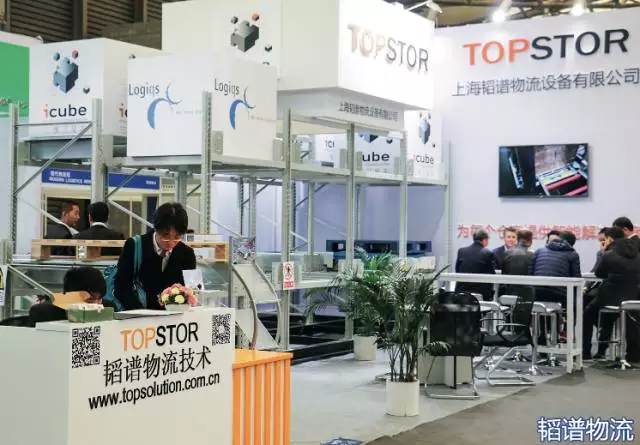

The first exhibition CeMAT Asia Shanghai Tao spectrum logistics equipment Co. Ltd. (hereinafter referred to as "Tao spectrum logistics"), dedicated to the world's most advanced warehousing logistics technology and equipment into the China market. The exhibition, Tao spectrum logistics and the three leading international logistics equipment suppliers, Holland Logiqs B.V., Italy Spaggiari logistics company logistics automation Automation Co. Ltd., Germany AFB fork joint exhibition company.Among them, iCube three-dimensional satellite vehicle system Logiqs B.V. display mainly for automatic storage pallets of goods, and four to the shuttle "goods to people" system, can also be on the shelves in the cross channel, cross shelf flexible operation, its carrying capacity reached 1.5 tons; Spaggiari automatic warehouse (shuttle car satellite car body) light, the use of modularization, 8 driving wheels in achieving the best performance and to ensure greater stability and reliability, but also with AFB display Miniload forklift operation; the fork is lightweight, reliable performance, high work efficiency, speed up to 2m/s. The home debut at the CeMAT Asia exhibition companies have said that he was very optimistic about the market China, confident in the development of a China.

Kunming Kunchuan Logistics Information Industry Company Limited (hereinafter referred to as "Kunchuan logistics") started in 1995, after 20 years of temper, has now become the solution providers and system integrators leading domestic logistics automation systems and equipment industry in.

This exhibition, focusing on the overall solution of Kunchuan logistics provide consulting project planning, project design, system simulation, optimization design, manufacturing, installation and commissioning, customer service service one-stop logistics system, emphasizes the integration of the supply chain service concept.Kunchuan logistics deputy general manager Gan Zhongping in an interview with reporters pointed out that last year the company products on display, this year basically has blossomed. Systems integration company this year is mainly the pursuit of industry application breakthrough, breakthrough, and product maturity and reliability breakthrough. Kunchuan now mainly do the logistics, the logistics technology is relatively mature in many industries, and from pure storage technology to "storage + distribution + production process automation"; in addition, the application of logistics technology to the whole supply chain, a gradual transition from Department of logistics service enterprise to the whole supply logistics service chain. Gan Zhongping said, at the end of this year or will Kunchuan logistics integration depth, the whole logistics business into one division, forming a vertical structure, the ability to provide products and services become more and more powerful, and better meet the increasing market demand of logistics.

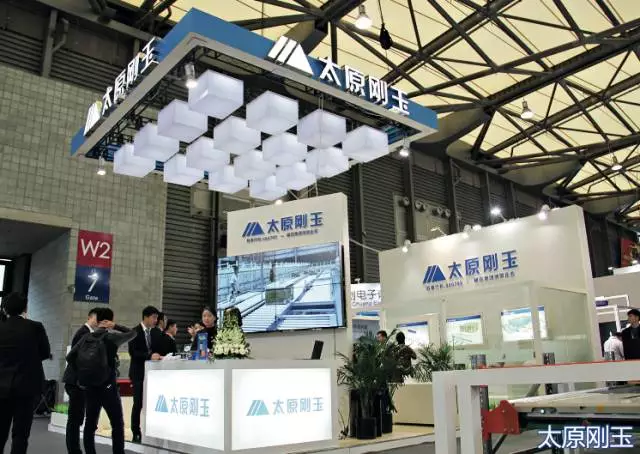

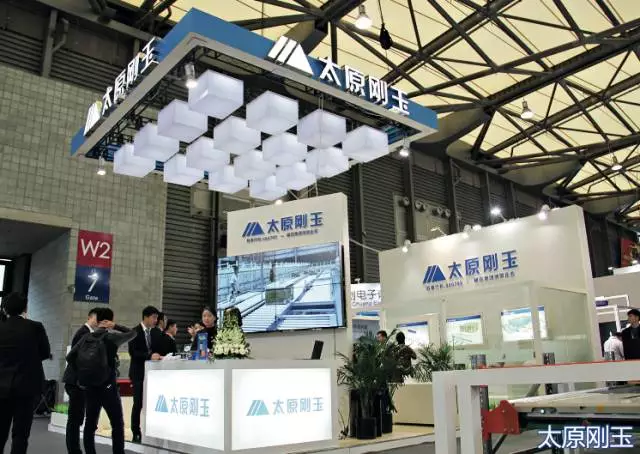

Taiyuan Gangyu Logistics Engineering Co. Ltd. (hereinafter referred to as "Taiyuan corundum") is a wholly owned subsidiary of Hengdian innuovo Technology Corporation group, mainly engaged in integrated logistics automation systems and related equipment R & D and production. The exhibition, Taiyuan corundum on the display of its integrated supply chain solutions, full service automated logistics system installation for customers from the project planning, equipment manufacturing, software development; in addition, combined with the specific case, Taiyuan corundum also demonstrated its production material management, finished products warehouse, all channels of distribution center the application of logistics technology. Taiyuan corundum chairman Yao Xiangsheng said that with the further development of the industry and the change of customer demand, to provide integrated design and service for customers to become the industry trend. Therefore, now Taiyuan corundum to undertake the basic project to expand the design and service of integrated logistics system, according to the actual needs of customers to solve tailored one-stop logistics solutions. In the future the company will further increase marketing efforts in electricity, shoes and clothing, medicine, household appliances and other fields.

Shenzhen Tianda CIMC Logistics System Engineering Company Limited (hereinafter referred to as "Tianda CIMC CIMC") is engaged in the automated warehouse and material handling systems engineering planning, design and integration, and professional core logistics equipment manufacturing company. This year the Tianda CIMC is the main push of the "integrated one-stop solution for the logistics system, the application of advanced logistics equipment and control system, to provide customers with factory logistics system integration, logistics center system integration, automated warehouse system integration at different levels of the logistics system of turnkey project". Tianda CIMC sales director Chinese in the District, pointed out that the outstanding advantages in Tianda CIMC: planning and integration of professional experience in logistics system has more than 20 years, with advanced design concept and perfect design method; has a more than 100 person R & D team, can keep the leading technology; set up customer service service network covering the whole world 24 hours, can respond to customer service requirements.

Wuxi Zhongding logistics equipment Co., Ltd. (hereinafter referred to as "Ding integrated") new company logo brighten. According to the company's deputy general manager Weng Zhongjie introduced a new brand slogan "good master", expressed in Ding integrated customers and partners, to all employees to create economic benefits, but also will be more focused on providing solutions for the integrated logistics system for users to resolve. In the exhibition of the latest Ding integrated solutions for new energy lithium industry logistics integration system, and show the simulation link segments of intelligent manufacturing loading and sorting of two links, which applied the three coordinate robot, the precision can reach 0.1 mm, this scheme can also be applied to parts, electronics, pharmaceutical and other industries. In addition, Ding also integrated model to show the high warehouse, goods at "picking system and review of packaging and cross belt sorting delivery system, visually demonstrate the advantage of the system and process design.

At present, the rapid development of electronic commerce in China, but also in the rapid rise of intelligent manufacturing, which requires logistics system integrators for enterprise customers to provide more rapid, accurate, timely, efficient and RuChuKu picking system. In this year's CeMAT Asia exhibition, "goods to people" system has become a major bright spot, many enterprises in the booth can see.

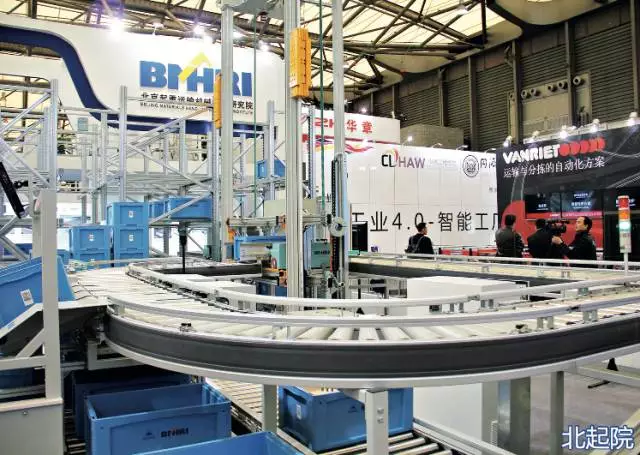

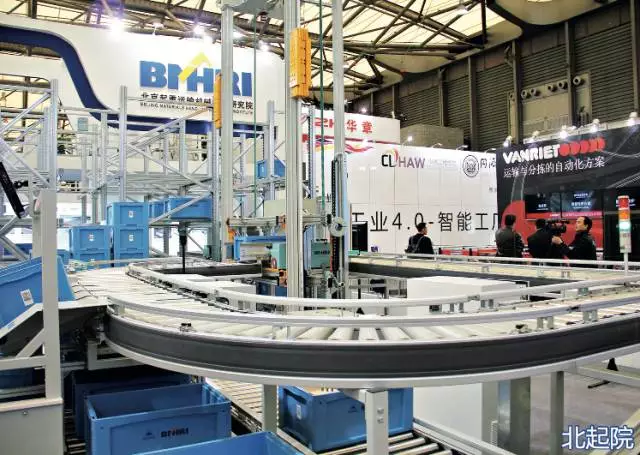

Deep in the field of logistics for Beijing lifting transport machinery design and Research Institute (hereinafter referred to as "North"), has a deep understanding and knowledge for the logistics system integration services. North Hospital close to the industry needs of exhibitors this year focused on the introduction of "goods to the" picking system, including multi shuttle systems, cross belt sorting system, "goods to people" to choose platform. North Institute of logistics warehousing project department deputy general manager Meng Lingguang introduction, the system is mainly used for fast access and selection of goods, with high storage density, high picking efficiency and reducing labor intensity and save the amount of labor and other advantages, is widely used in many fields of electricity, medicine, retail and manufacturing etc.. In the eyes of Meng Lingguang, with the development of the industry continues to mature, the logistics system integrators will move towards more segments of the market in the field of digging through the strength of the mighty wave crashing on a sandy shore, enterprises will be truly professional and evergreen foundation. Therefore, attention will be professional, north of the future development of the concept of.

Beijing Machinery Industry Automation Research Institute (hereinafter referred to as "from the north") presented the latest "delivery" picking system solution, by the audience attention. According to the deputy director of the North self Logistics Technology Engineering Center Wang Yong introduction, from the north to provide goods to people picking system solution has the advantages of high density, high efficiency, intelligent and low cost. The system is composed of multi shuttle, high density shelves, picking workstation and conveyor equipment, etc., through a unified management information system, scheduling and optimization, implementation of "goods to people" to choose. Compared with the traditional way of sorting, this solution can improve the storage utilization rate of about 50%, improve the picking efficiency 2 to 5 times, picking up to 99% accuracy, suitable for manufacturing, food, medicine, electronic commerce, cold chain and other industries. On the first day of the exhibition, from the north and the EUROFORK company also held a multi shuttle system of strategic cooperation signing ceremony, the two sides will promote each other, to achieve the depth of cooperation, to jointly develop the market Chinese, better customer service. It is reported that in 2016 the north since the great development, sales among the best in the industry.

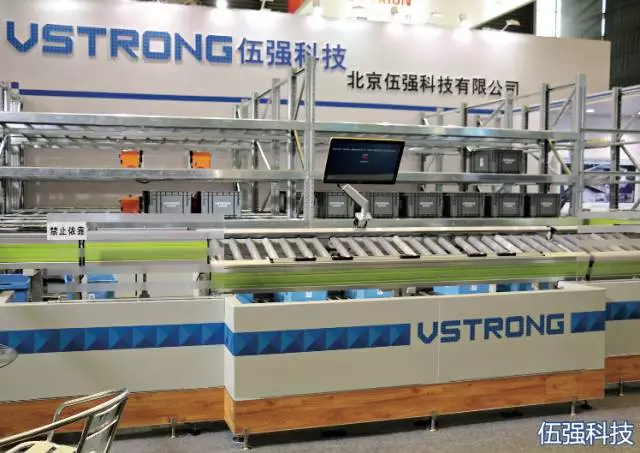

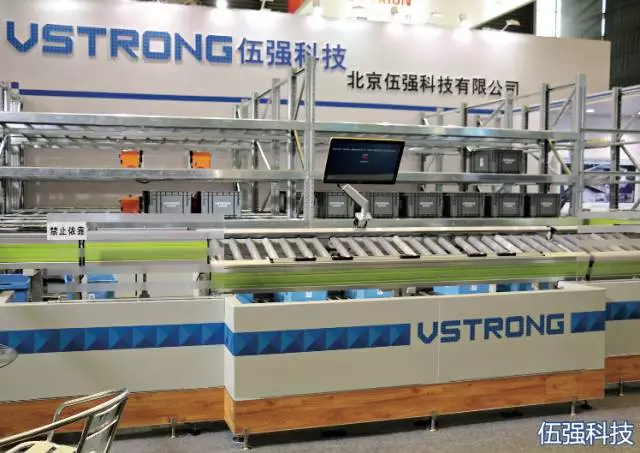

Beijing Wu Qiang Technology Co. Ltd. (hereinafter referred to as "Wu Qiang technology") as the leading domestic logistics system integrators, its new "goods" zero solution to the four shuttle "goods to the" picking system for the booth pocketed popularity. The system is composed of dense storage shelves system, four to the shuttle system, transportation system, information system, computer workstations, chosen for storage box, package library review system composed of 7 subsystems, due to space limitations, the exhibition site on the display of the 5 sub system. Four of them to the shuttle vehicle speed of up to 4m/s, can achieve more than 1 cars or a roadway tunnel multiple shuttle flexible operation, effectively solves the problem of the warehouse logistics tasks such as uneven roadway. The platform is chosen by 1V4 (1 picking personnel at the same time picking 4 goods turnover box) of the picking, the future will continue to increase to 1V16 or even 1V20, further enhance the degree of concentration. For the goods to the person "system in the domestic market development, Wu Qiang Technology Vice President Qu Xiaotong believes that the opportunities and challenges.

The same show "goods to people" system and Jiangsu Huazhang logistics Polytron Technologies Inc (hereinafter referred to as "Huazhang"), which is China debut at the CeMAT Asia exhibition. In fact, China began early in 2006 "goods to study" technology, and access to a number of "goods to the patent technology" in 2007. This chapter shows the "goods to each subsystem" system, such as the shuttle system has achieved many upgrades, is a very mature technology. Chinese Vice President Hua Juliang said, "this set of goods to the people" the most prominent system lies in the control of the software system, such as order processing OPS system upgrade, so as to enable the system to achieve higher efficiency and accuracy. According to reports, the system can achieve 980 times per hour picking efficiency.

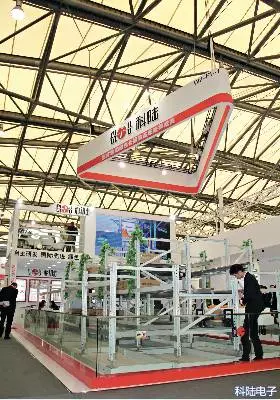

This year's CeMAT Asia exhibition, Shenzhen CLOU electronic Polytron Technologies Inc (hereinafter referred to as the "CLOU Electronics") on the display of the multi intelligent and highly efficient, green shuttle storage solutions.

According to CLOU electronic automatic control department deputy general manager Chen Ningjun introduction, the company's intelligent wear car storage solutions, composed of dense storage shelves, wear car lifting machine, high speed cargo lifting machine, intelligent car, wearing roller conveyor line and the central dispatch system, suitable for a variety of rapid access to goods shelves in the form of that is efficient, reliable and stable characteristics, storage capacity and processing capacity can be extended according to different storage requirements, greatly enhance the efficiency of space utilization and access operation, wide application of the market, has brought a revolutionary innovation as the material box, carton goods storage, sorting, sorting.

The foreign enterprises in the product stability and adaptability is very important to see. With the China market demand for logistics automation equipment to increase obviously, has a good reputation and credibility in the fork industry MIAS (Mias) will undoubtedly provide a huge space for development. As CeMAT Asia, MIAS "regulars" exhibition this year focus shows two carton special telescopic forks except heavy telescopic forks -- Viper x series. Among them, Viper x 2 high speed telescopic forks can handle two bins, greatly improve the picking efficiency; Viper x 1 telescopic forks have the advantage of no need to adjust the spacing of the fork.Viper X series of products for a variety of different materials, different sizes of cartons designed for material handling to achieve flexible and efficient cargo size, can also be applied in the -24 C storage environment. Because the MIAS has entered the Chinese market for many years and successfully realize the localization of production, its product is undoubtedly more price competitive advantage.

As one of the leading international stacker equipment providers, Rob Taco this year's show the main product is MiniLoad series material box type stacker. This series of products with a high degree of flexibility and adaptability, can provide different solutions according to different customer needs; the shelf height up to 20 meters, the weight of the goods at this height can still bear the 150kg; walking speed of up to 6 meters / sec, acceleration up to 3.5 meters per second squared. In addition to the MiniLoad stacker, Rob Taco launched products include standard pallet stacking machine, high speed and light load, multi shuttle stacker system etc.. Rob Taco automation technology (Suzhou) Co., Ltd. Mr. Hannes, chief technology officer said Robert Tektronix has many advantages: it is designed according to the technical standards and international leading production, continue to provide products of high performance and high reliability; the two is to have a rich product line and custom design ability, maintain a long-term and stable cooperation with many integrators at home and abroad; the three is adhering to the "in Chinese, for China, development strategy and the world", and actively promote the localization of technology research and development, is committed to providing international standards, cost-effective, the most suitable solution.

The exhibition, TGW logistics group FlashPick solutions caused widespread concern. Regardless of the size of orders, or express orders, fast processing of goods, or are extensions of layout flexibility and the process of the actual operation of the FlashPick system can cope with ease, and always maintain the "fast and flexible", is a full range of channels and distribution of the most ideal solution of. In addition, there is a "wild" of the new generation of TGW Mustang R (Mustang Revolution) stacking machine is greatly improved. The properties such as: highly hitherto unknown (up to 25 meters deep); four bit storage, significantly improve the space utilization rate; adaptation of TGW logistics group is some type of fork that reduces the customer system upgrade project cost; the use of such innovative anti swing control; support monitoring equipment operation based on the tablet computer, customers can easily see the system operation status. TGW booth on the "VR equipment" is also popular. The audience can bring on a virtual reality glasses, with experts in the field to explain the first perspective of logistics center close watch solutions, experience the wisdom of the logistics center, explore the new world logistics.